BetonRadiant Styr XPS

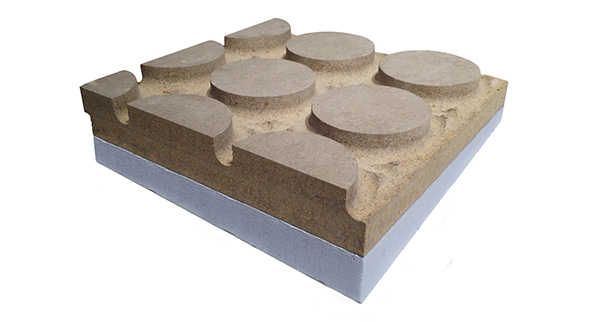

Beton Radiant Styr XPS is a modular system to obtain a radiant heating floor systems and consists of a cement bonded particle board with high density (1350 Kg/m³) according to European standard EN 13986, and an insulating extruded polystyrene panel.![]()

![]()

![]()

![]()

![]()

Related products

Beton Radiant Styr XPS is a modular system to obtain a radiant heating floor systems and consists of a cement bonded particle board with high density (1350 Kg/m³) according to European standard EN 13986, it has high compression resistance equal to 9000 kPa, and an insulating extruded polystyrene XPS.

Beton Radiant Styr XPS consists in an excellent solution to obtain a radiant heating floor system with condensing boilers. The system can also be used in ceilings and on internal walls, thus eliminating both radiators and air conditioners.

The radiant floor Beton Radiant Styr XPS is a modular system and suitable for any finish, ensuring an excellent ease of installation and flexibility, which makes it ideal for the realization of radiant floor heating systems.

The cement bonded particle board is modeled on the upper face to receive and lock the floor heating pipes, while the other constitutes the underlying layer, insulating, in extruded polystyrene CE certified. The upper panel after laying the pipes and filling the joints is suitable for any surface coating, chosen by the user.

The two panels are coupled in the factory with a patented system and the wood used in their processing comes from forests controlled by reforestation cycles and pressed with water and hydraulic binder (Portland cement) with high cold compression ratios.

| Cement bonded particle board thickness (mm) | |||

|---|---|---|---|

| Extruded polystyrene thickness (mm) | 20 | 20 + 20 | |

| 10 | • | • | |

| 20 | • | • | |

| 30 | • | • | |

| 40 | • | • | |

| Available dimensions | ||

|---|---|---|

| Two panels coupled in cement bonded particle board and extruded polytyrene | 1200 x 500 | |

On request it is possible to produce different formats for minimum quantities of 300 square meters.

On request it is possible to realize housing distances for pipes larger than 14 mm (standard size), up to a maximum of 17mm. With a cost increase of 5%.

BetonWood cement bonded particle boards

| Density (kg/m³) | 1350 |

| Fire reaction according to EN 13501-1 | A2-fl-s1 |

| Thermal conductivity coefficient λD W/(m∗K) | 0,26 |

| Specific heat [J/(kg∗K)] | 1880 |

| Resistance to vapor diffusion μ | 22,6 |

| Coefficient of linear thermal expansion α | 0,00001 |

| Thickness swelling after 24h of permanence in water | 1,5% |

| Air permeability I/min. m² Mpa | 0,133 |

| Surface PH value | 11 |

| Compressive strength (kPa) | 9.000,00 |

| Resistance to transverse traction (kPa) | 500,00 |

| Resistance to cutting (kPa) | 500,00 |

| Elasticity module E (kPa) | 4.500,00 |

extruded polystyrene insulating panel

| Densità (kg/m³) | 15÷35 |

| Fire reaction according to EN 13501-1 | E |

| Thermal conductivity coefficient λD W/(m∗K) | 0,026÷0,036 |

| Specific heat [J/(kg∗K)] | 1450 |

| Resistance to vapor diffusion μ | 50÷100 |

| Compressive strength at 10% of deformation (kPa) | 120÷250 |

The system is also available in the version coupled directly in the factory with an insulating layer, which improves the radiating capacity of the entire package.